Technical Information from Testemp Ltd > Thermocouple

We manufacture and distribute a wide range of temperature sensors throughout the UK.

Please feel free to contact us on +44 (0) 1903 714140 for any questions about our products.

Alternatively you can email sales@testemp.co.uk or fax +44 (0) 1903 717435.

Thermocouple

Basic principle

The Seebeck Effect – if a circuit is made by joining two wires of different metals, any difference in temperature between the joints will produce an EMF(Electro Motive Force) which will cause a current to flow in the circuit. Using favourable materials, this EMF(Electro Motive Force) will be of the order of 3 to 5 millivolts per 100°C difference between the junctions, and has an approximately linear relationship to temperature.

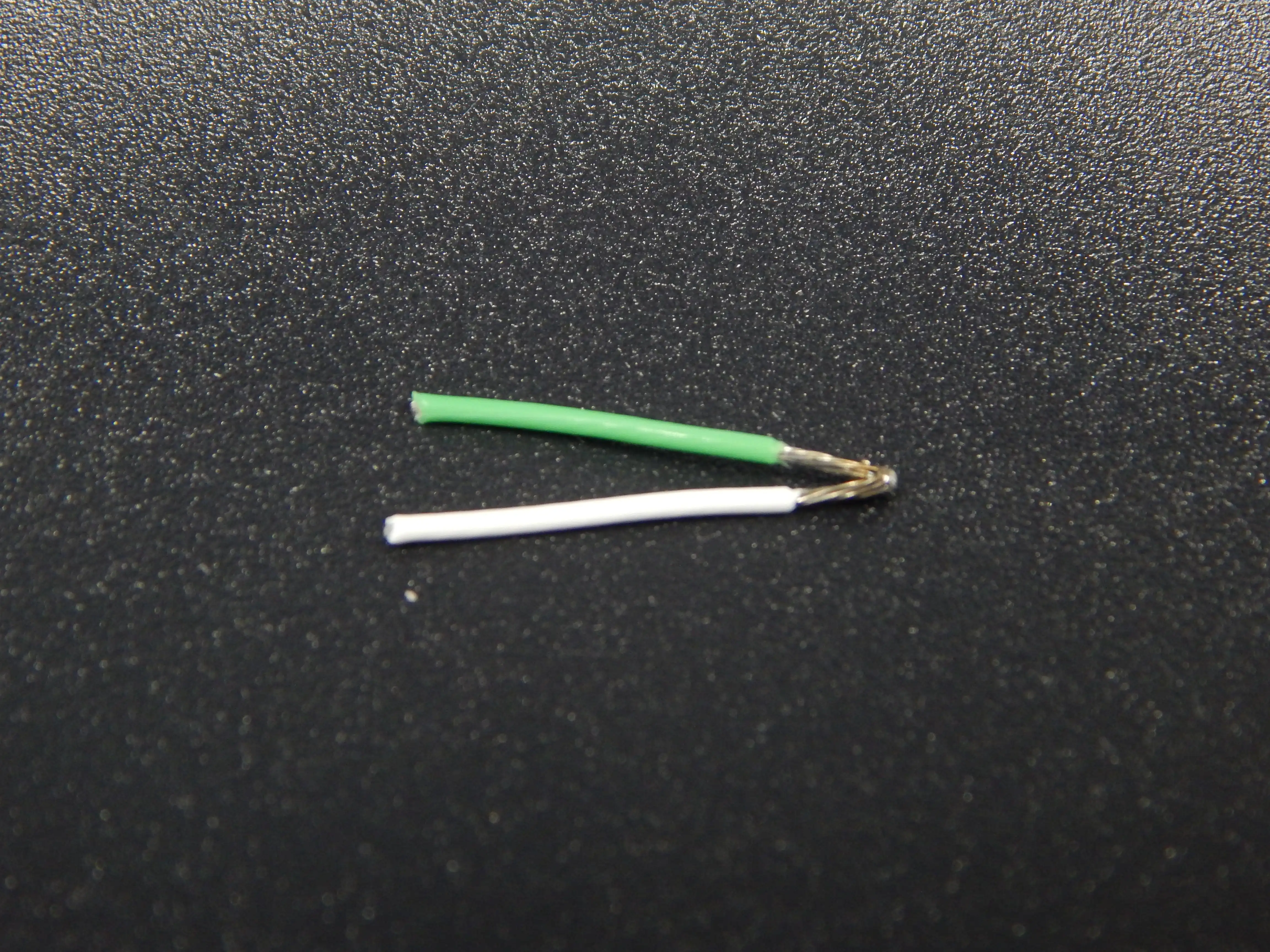

Element materials and colour coding

Thermocouple elements available from Testemp are as follows:

Type J and L Iron (+) strongly magnetic Constantan (-) not magnetic

Range : 0 to 750°C

BS colour coding Yellow (+), Blue (-)

IEC colour coding Black (+), White (-)

American colour coding White (+), Red (-)

German colour coding Red (+), Blue (-)

Japanese colour coding Red (+), White (-)

Type K Nickel/Chromium (+) not magnetic Nickel/Aluminium (-) lightly magnetic

Range : 0 to 1100°C

BS colour coding Brown (+), Blue (-)

IEC colour coding Green (+), White (-)

American colour coding Yellow (+), Red (-)

German colour coding Red (+), Green (-)

Japanese colour coding Red (+), White (-)

Type T Copper (+) not magnetic Constantan (-) not magnetic

Range : -200 to 300°C

BS colour coding White (+), Blue (-)

IEC colour coding Brown (+), White (-)

American colour coding Blue (+), Red (-)

German colour coding Red (+), Brown (-)

Japanese colour coding Red (+), White (-)

Type E Nickel/Chromium (+) not magnetic Constantan (-) not magnetic

Range : 0 to 800°C

BS colour coding Brown (+), Blue (-)

IEC colour coding Purple (+), White (-)

American colour coding Purple (+), Red (-)

German colour coding Red (+), Black (-)

Japanese colour coding Red (+), White (-)

Type N Nickel/Chromium/Silicon (Nicrosil) (+) not magnetic Nickel/Silicon/Magnesium (Nisil) (-) not magnetic

Range : -200 to 1250°C

BS colour coding Orange (+), Blue (-)

IEC colour coding Pink (+), White (-)

American colour coding Orange (+), Red (-)

German colour coding Orange (+), Red (-)

Japanese colour coding Orange (+), Red (-)

The temperature ranges listed above are for long-term use. Most types will withstand temperatures outside these limits for short periods.

Selection of thermocouple type

The choice of thermocouple type will be determined mainly by the range and cost. In cases where replacement sensors are required, the thermocouple type will usually be dictated by the existing instrumentation.

Limitation of use in ambient temperature range

Because the output signal is dependant upon the difference in temperature between the sensing junction and the reference junction (often called the cold-junction, and usually situated inside the measuring instrument), thermocouples are not suitable for measuring or controlling temperatures close to ambient unless the system for measuring the reference junction is exceptionally good. Where low-cost industrial instruments with built-in reference junctions are used, thermocouples are generally not considered to be suitable for use at temperatures within 60°C of that of the instrument.

Accuracy

The accuracy of thermocouples depends upon the quality of the element materials, and three classes of accuracy are defined by British Standards. Similar classifications apply to other national standards.

Grounded and isolated junctions

Thermocouple assemblies may be manufactured with the sensing junction grounded to the sheath or electrically insulated (“isolated”) from it. Grounded junctions are usually cheaper to produce and have a faster response, but some control systems will function correctly only with isolated junctions.

Leadwire extension

Whenever a wire in a thermocouple circuit is joined to a wire or terminal made of a different material another thermocouple will be created at the joint. If such connections between the sensing junction and the measuring instrument are at temperatures different from that of the reference junction, errors will be produced. When thermocouple leads are extended it is therefore essential to use cable made of the same materials as the thermocouple or of materials which have the same thermoelectric characteristic at the temperatures likely to occur at the joints. Cable with conductors of the same materials as the thermocouple element is referred to as extension cable, whereas cable with conductors of cheaper materials with similar characteristics is known as compensating cable. As a general rule compensating cable should not be used if the temperature at the joints exceeds 100°C.

Similarly, if plugs and sockets or terminal blocks are used in thermocouple circuits, the contacts or terminals should be of the same material as the thermocouple element. Plug and socket connectors and terminal blocks of this type are available from Testemp.